Narrow Path 3D

FILAFLEX 70A Sample Size 25g, Best Ultra Soft TPU Flexible 3D Printing Material US, 1.75mm-

FILAFLEX 70A Sample Size 25g, Best Ultra Soft TPU Flexible 3D Printing Material US, 1.75mm-

Couldn't load pickup availability

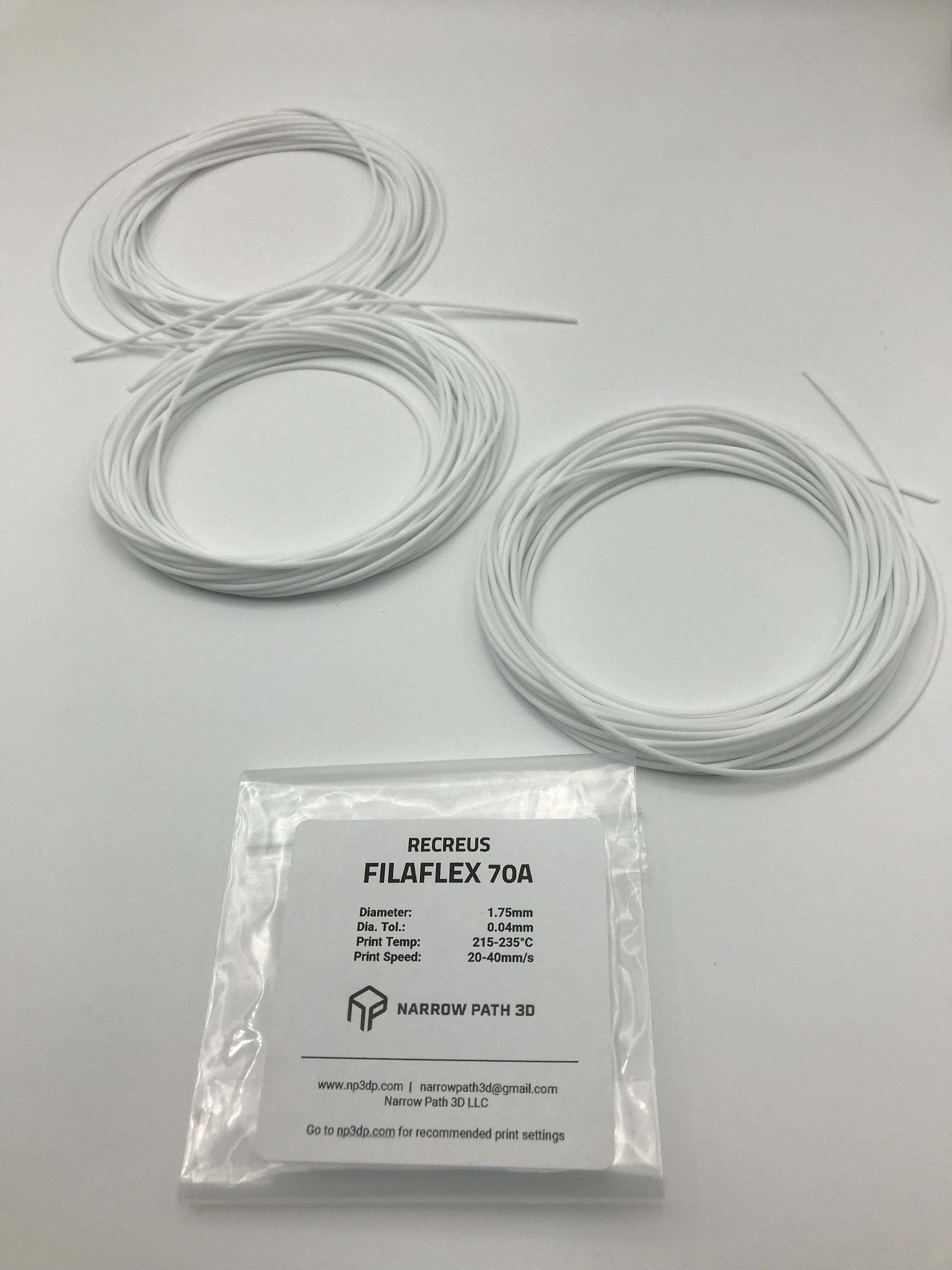

SAMPLE - FILAFLEX 70A

Filaflex 70A, ’Ultra-Soft’, is a highly elastic and advanced flexible filament from the Filaflex range for 3D printers.

- Shore hardness 70A

- 900% stretch

- High elasticity

- Resistant to solvents, fuel and acetone

- Odorless

- No hotbed required

- Made in the EU

Notes: Not suitable for All Metal hot-ends.

Sample Info:

This is a 1X pcs. 25g sample for testing and comparing different elasticities to help you find the right material for your project.

SIMPLY FLEX

Filaflex 70A, 'Ultra-Soft', is a highly elastic TPU (thermoplastic polyurethane) flexible filament whose properties make it comparable to silicone.

It has a 70A shore hardness, reaching up to 900% stretch before breaking. Its greatest advantage is that after stretching, it returns to its original shape without deforming or breaking.

Filaflex 70A is not suitable for All Metal hotends, since the filament could get stuck and not flow properly, however, if you have any questions, contact us and we will advise you.

The filaments of the Filaflex range have great print bed adhesion, so they don’t need a heated bed, blue tape, Kapton tape, lacquer or any other spray adhesive. What’s more, they are odourless and resistant to solvents, acetone and fuel. Different guidelines are required for printing with Filaflex. That’s why the 3D printer needs to be properly configured.

How to get started with Filaflex? First of all, we recommend this article on how to print with flexible materials written by Steve Wood of Gyrobot.

APPLICATIONS

Filaflex 70A is non-toxic and may come in contact with the skin. Consult for medical or food use. Ideas to create:

– Insoles: orthotic insoles.

– Prostheses and models of organs: prosthetic arms and hands, organs for simulation of surgical operations, etc.

– Flexible objects and parts for manufacturing and the automotive industry: stoppers, joints, tyres, grippers, etc.

– Textile parts and accessories: textile garments, fabrics, prints on garments, bags, earrings, etc.

– Footwear: soles, shoes, sandals, slippers, etc.

TECHNICAL DATA

Basic Print Settings to get started:

Print temperature: 215-235 °C.

Print speed: 20-40 mm/s.

Diameter tolerance: 0.04 mm.

Retraction speed: 35-50 mm/s at a distance of 2.5-6 mm/s.

Travel speed: 160-200 mm/s.

Layer height: 0.08-0.3 (for 0.4 mm nozzles). Optimal results 0.2 mm.

TDS and MSDS:

Share