Which 3D Printing Material is Most Flexible and Will It Work For Me?

Share

Which 3D Printing Material is Most Flexible and Will It Work For Me?

We're comparing Fiberlogy flexibles and figuring out which one is best suited to your needs.

What you need to know at a glance:

- All flexible Fiberlogy materials (FiberFlex, MattFlex, PP or Polypropylene) are versatile, highly durable, have excellent resistance to chemicals, highly flexible and easy for even beginners to print.

- Some materials are easy to get started printing, especially if you are new to 3D printing.

- One of the keys to successfully printing flexible 3D printing material is having the right set up.

- You can always make the less ideal extruder work, but the ones designed specifically for flexible filament are going to deliver better results faster, with less hassle.

- Fiberlogy Flex filaments do not absorb water *quickly* but it is always recommended to keep your filament stored in a dry location when not in use and to dry the material before each print to rule out excess moisture as a possible factor for failure.

Discover Something New: Printing Flex Means New Opportunities

Should you be printing with rubber? Fiberlogy has been the leader in creating durable, reliable flexible filaments for 3D printing. These materials are also very easy to get started with if you're new to flexible filament.

They also recently launched the new MattFlex 40D - a flexible filament with a unique matte finish instead of the traditional glossy look. You can read more about MattFlex 40D and how it changes things for many printing possibilities in this article.

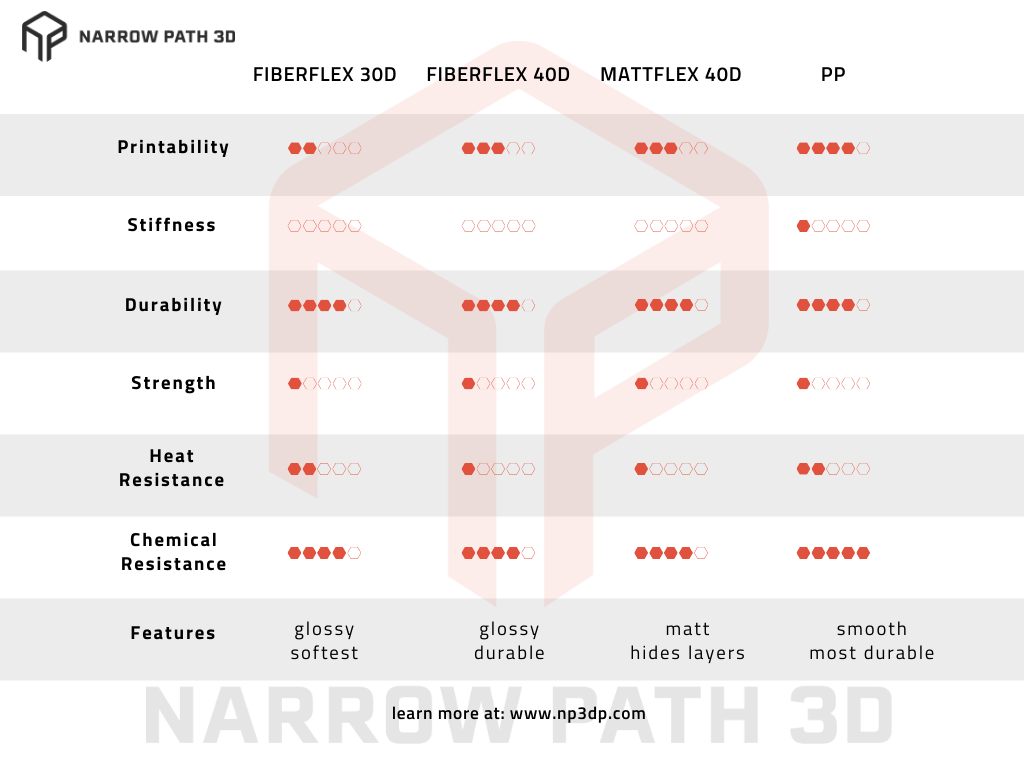

Use the chart below to compare different flexible materials and how they compare to each other.

Image: Chart comparing all Fiberlogy Flexible 3D printing materials FiberFlex 30D, FiberFlex 40D, MattFlex 40D and PP (polypropylene)

As you can see, they are very similar to each other with a few key exceptions. This makes it harder and easier to find the right material.

Harder because they are so similar in some ways (such as chemical resistance) it can feel hard to chose which will be ideal for your project.

In reality, it's easier because these materials are so similar on paper at least, that any of them could potentially work for the same project.

If you're feeling stumped or decision fatigue (exhausted from too many choices) we recommend trying a sample of each and doing some test prints to see for yourself.

Samples are the most cost effective way to try a lot of different materials at once and figure out for yourself which is best for you, not only reading about it and getting frustrated when you can't find a direct answer. Shop All Fiberlogy Samples Here

Below is each material with detailed specifications.

FIBERLOGY FIBERFLEX 40D

Fiberlogy 40D enables you to print faster flexibles with better accuracy, without disrupting the integrity of your prints.

Those new to flexible filaments can enjoy the ease of printing 40D, compared with softer flexible filament that can be more advanced and require more troubleshooting as well as slower printing speeds.

FIBERLOGY FIBERFLEX 30D

FIBERFLEX 30D allows you to create more flexible prints that stand up to high impact situations like tires, gaskets, etc.

30D offers more give and flexibility compared with 40D (softer and more flexible).

Both 30D and 40D are very flexible filaments and desired for many applications from fashion to big industry prototyping and end use items.

FIBERLOGY MattFlex 40D

MattFlex 40D enables you to easily create flexible prints with a beautiful Matte finish.

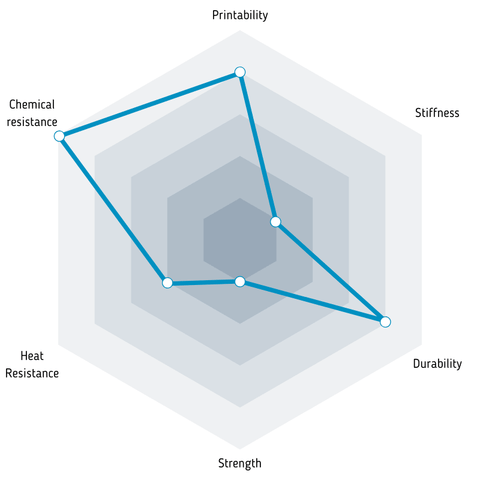

Image: MattFlex 40D Compared to FiberFlex 40D

Speed and Accuracy: Print faster flexibles (< 60mm/s) with better accuracy, without disrupting the integrity of your prints.

Easy: Those new to flexible filaments can enjoy the ease of printing 40D, compared with softer flexible filament that can be more advanced and require more troubleshooting as well as slower printing speeds.

Elasticity up to 6X times

FIBERLOGY PP

PP from Fiberlogy - Flexible and durable: prints designed with Polypropylene in mind can be some of the most durable prints achievable with todays materials

Attention to Detail: The molecular structure and raw materials gives PP excellent adhesion between print layers when printing

No fumes or odors

Non-toxic and suitable for contact with food: Prints created with proper printing parameters can even withstand household dishwashers and sanitization cleaning cycles.

Do you print with flexible 3D printing filament? Do you have any tips to add to this post? Let us know via email: narrowpath3d@gmail.com