Narrow Path 3D

Fiberlogy HIPS Filament - Dissolvable 3D Printing Support Material - 1.75mm, 0.85kg (1.87lbs)

Fiberlogy HIPS Filament - Dissolvable 3D Printing Support Material - 1.75mm, 0.85kg (1.87lbs)

Couldn't load pickup availability

Key Features:

- FIBERLOGY HIPS is characterized by its satin surface thanks to the addition of minerals, its excellent impact and water resistance, but most popular as the first choice for support material for ABS prints

- HIPS is easily dissolvable with d-Limonene which means not risking scraps or damage to your finished prints like traditional support removal; simply soak your print and remove the HIPS supports with minimal effort

- Excellent printing precision and similar print settings to ABS which makes it easier to dial in settings compared with more advanced materials

- A simple and cost effective choice for dissolving support material; HIPS has similar properties to ABS, which makes it a great choice for dual printing for support structures for ABS prints

- Lightweight Prints: When printed as the base material it is ideally suited for end use applications where the end object needs to be lighter than a material like ABS

- Engineered and created in Poland using highly specialized machinery and carefully selected raw materials

Samples Collection:

You can also order a HIPS sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the exact right material for your project.

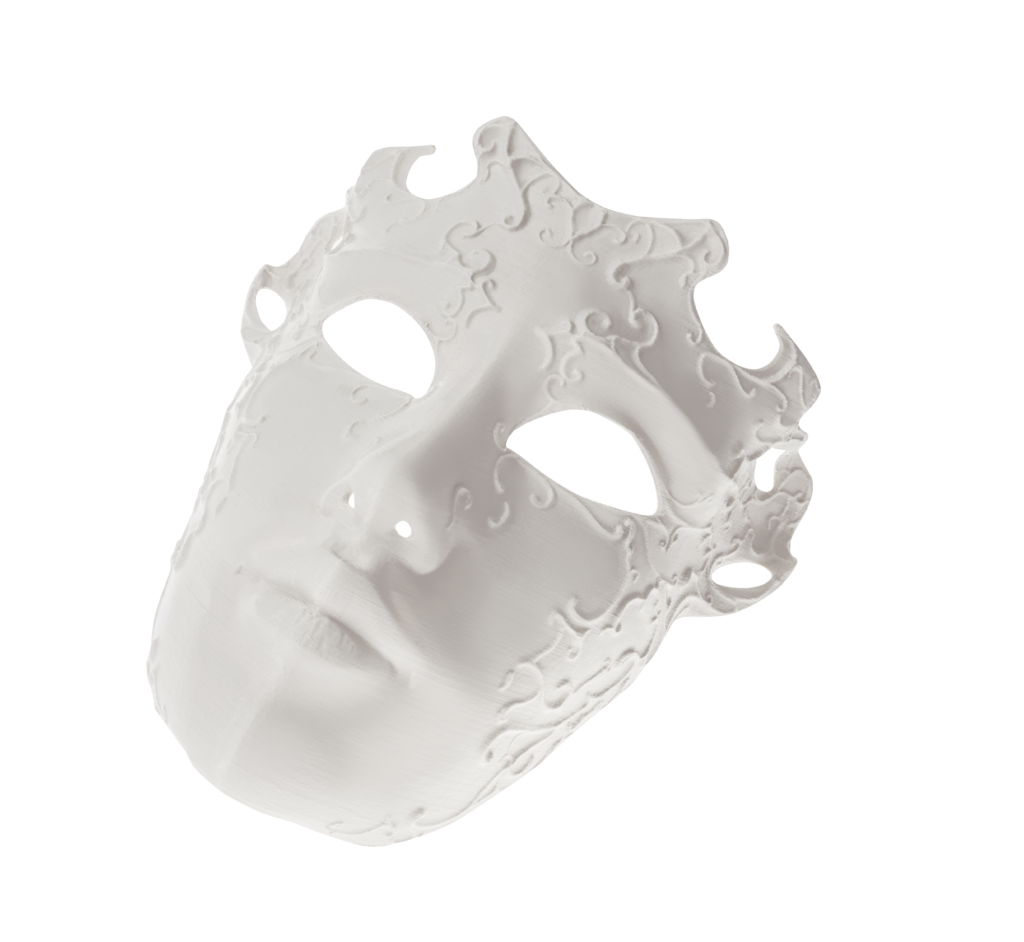

More Than the Base

HIPS filament is a base in both meanings of this word: its properties allow it to be used as a basic filament and also as a support materials for other filaments.

Using it in printing will give you a light and good-looking print with a matt surface. You can polish it and even coat it with acrylic paint. This allows each model or miniature to look very tasteful.

You can also decide to use it as a supporting material for prints that have large overhangs or non-standard shapes. You just need to immerse the print in D-limonene after this. It will dissolve the HIPS, leaving only the proper print.

Pro Tip:

If you experience bed adhesion issues we recommend an ABS slurry; you can easily make this yourself by dissolving pieces of ABS filament/small scrap ABS prints in acetone in a glass bottle (make sure the bottle has a tight, secure cap to prevent excess fumes).

After creating the slurry simply apply to your print surface before each print for a simple DIY adhesive.

Key to Successful Printing:

- We recommend a chamber for printing this material.

Printing Ideas and Applications:

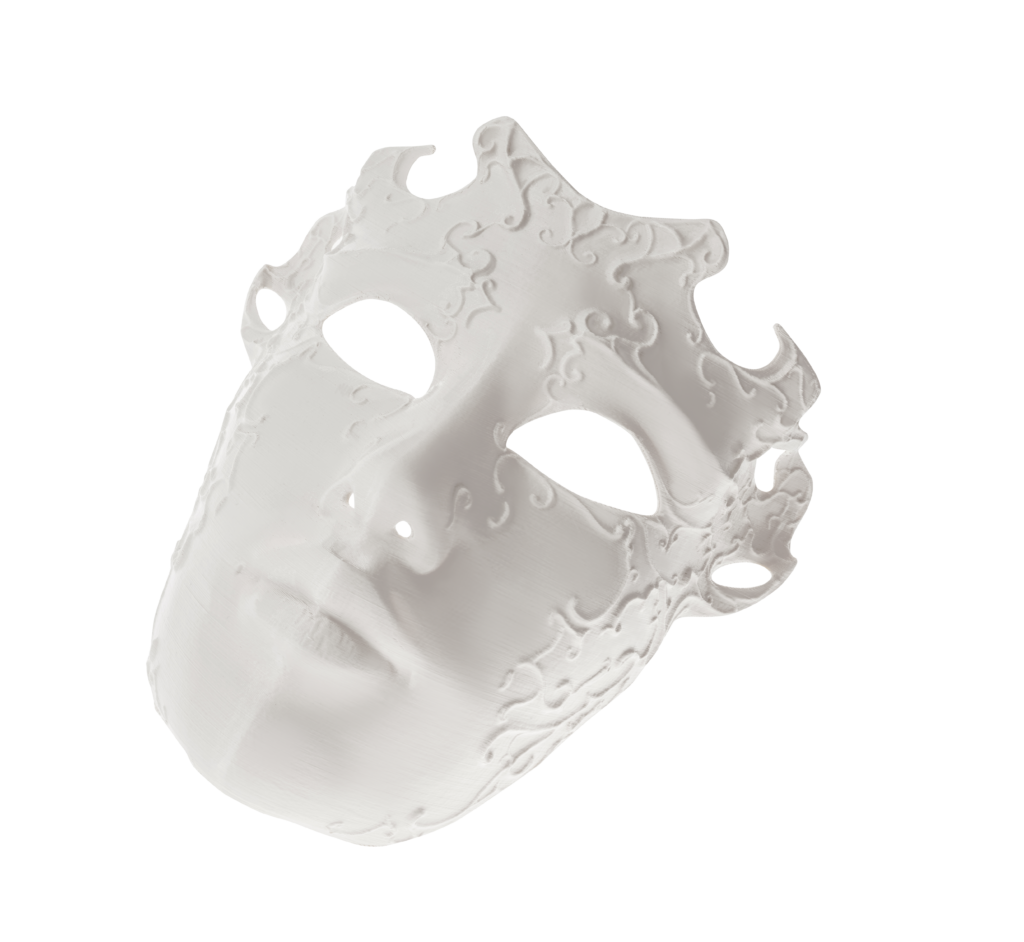

- Costumes or Their Elements: masks, parts of costumes, helmets

- Modeling: mock-ups, figures

- Prototypes: durable and lightweight elements

- Decor: decorations, hanging elements, lamps

- Joining with Other Filaments: support for other prints

How to Print:

Printing temperature: 230 – 245°C

Bed temperature: 80-100°C

Closed Chamber: recommended

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

TDS and MSDS:

Net weight : 0.85 kg

All of our materials have outstanding properties and parameters - diameter tolerance of +/- 0.02mm and oval tolerance of +0.01mm.

Share