Narrow Path 3D

FIBERLOGY PCTG - Professional Alternative to PET-G , 1.75mm, 0.75kg

FIBERLOGY PCTG - Professional Alternative to PET-G , 1.75mm, 0.75kg

Couldn't load pickup availability

Key Features at a glance:

- Fiberlogy PCTG offers excellent impact strength (up to 20X times greater than standard PET-G)

- Excellent chemical resistance (see TDS below for detailed resistances)

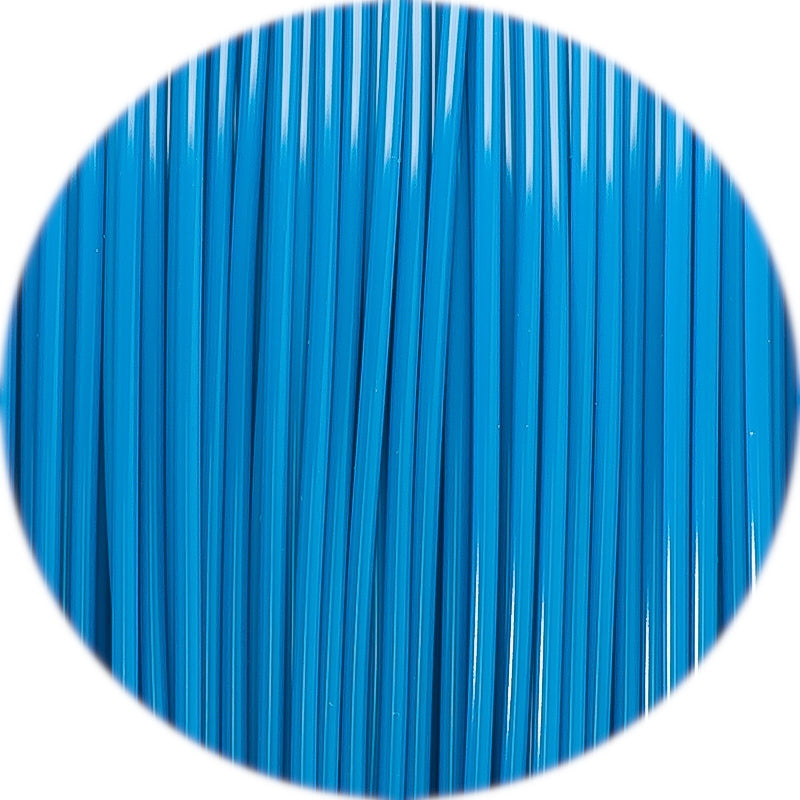

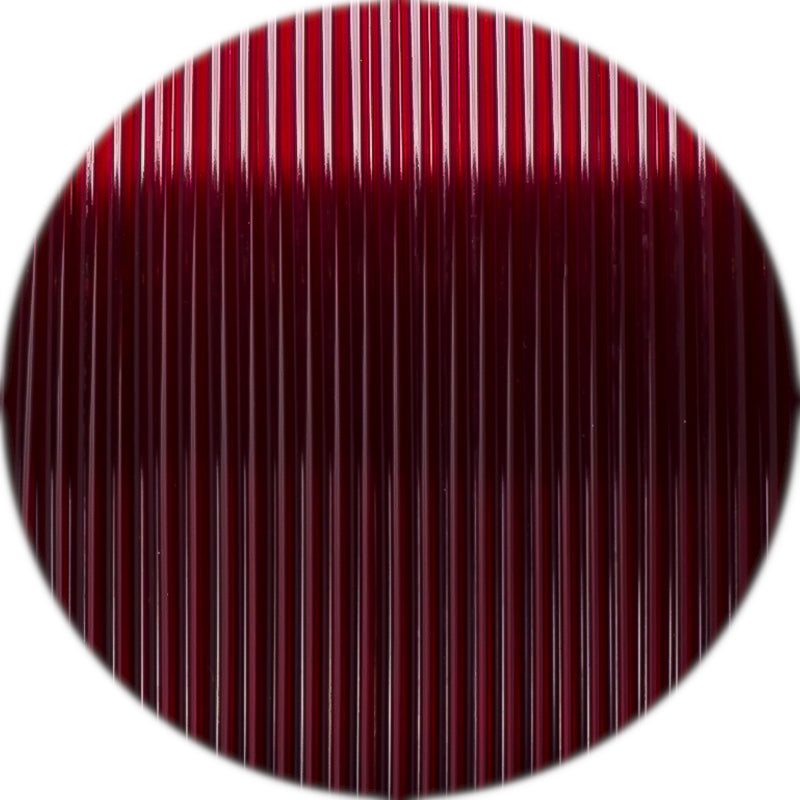

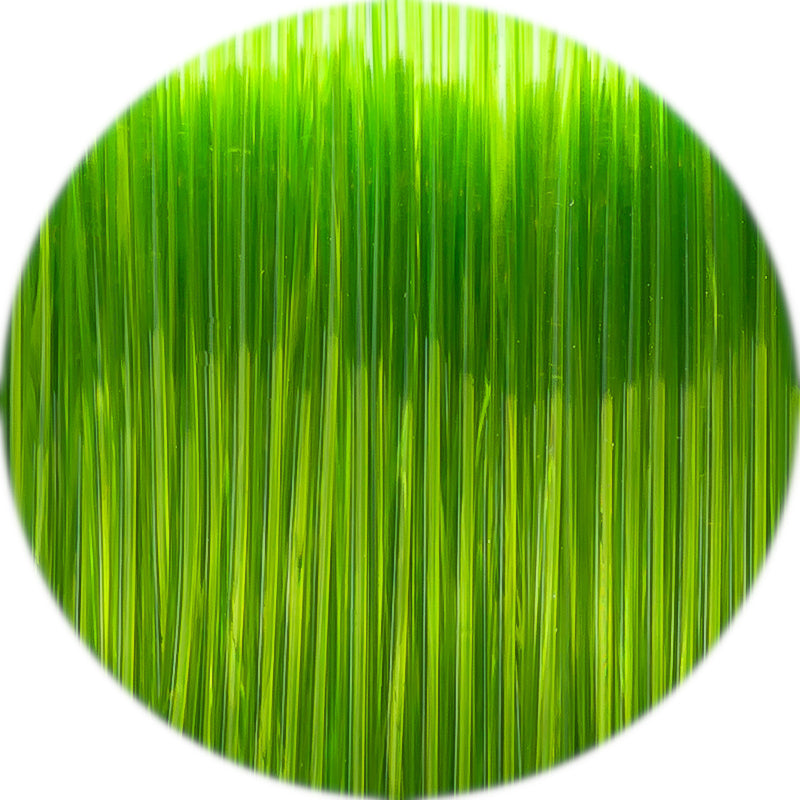

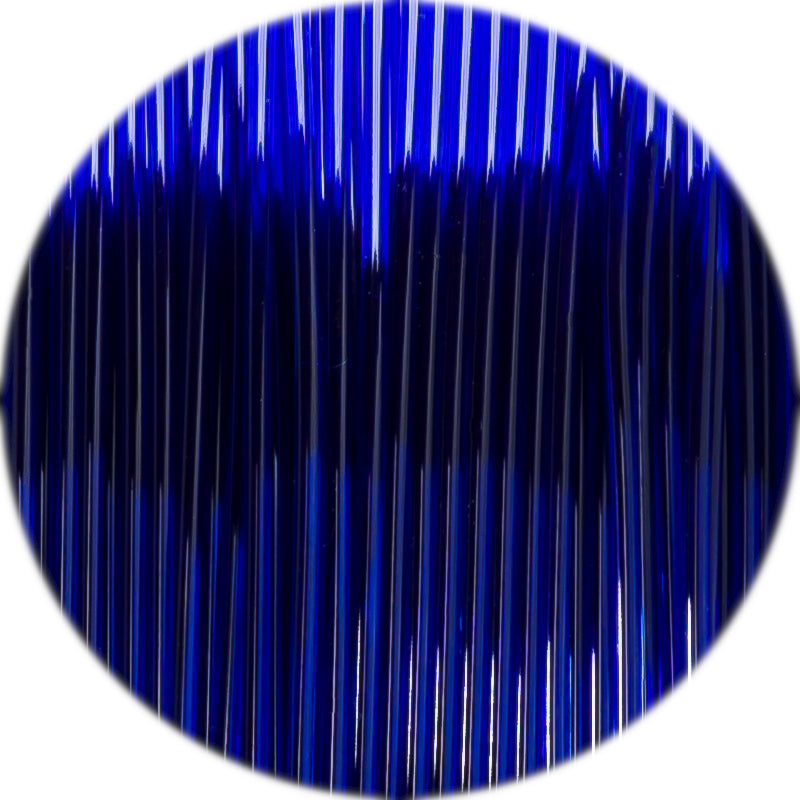

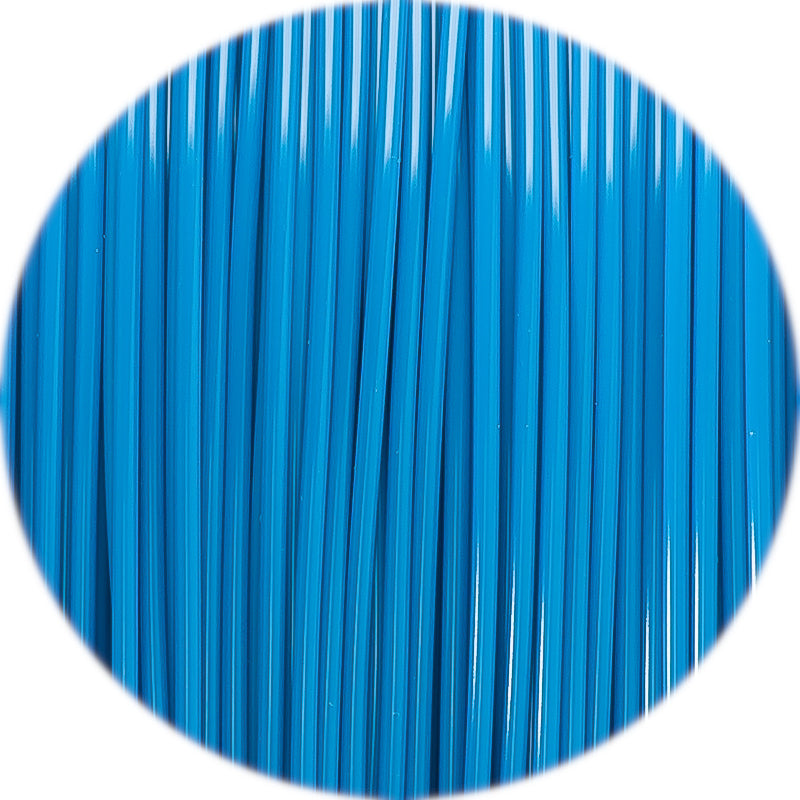

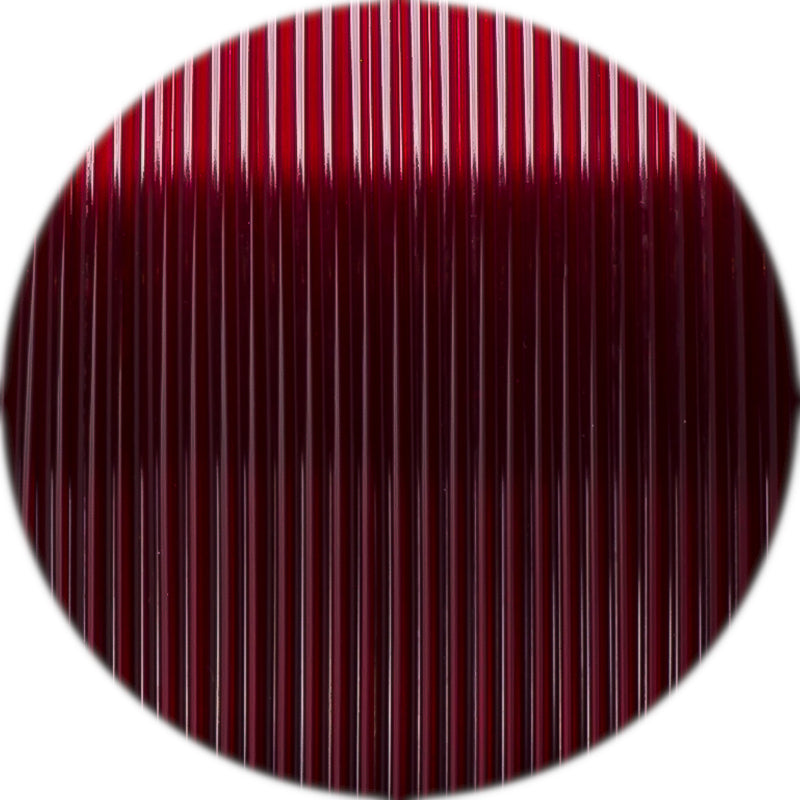

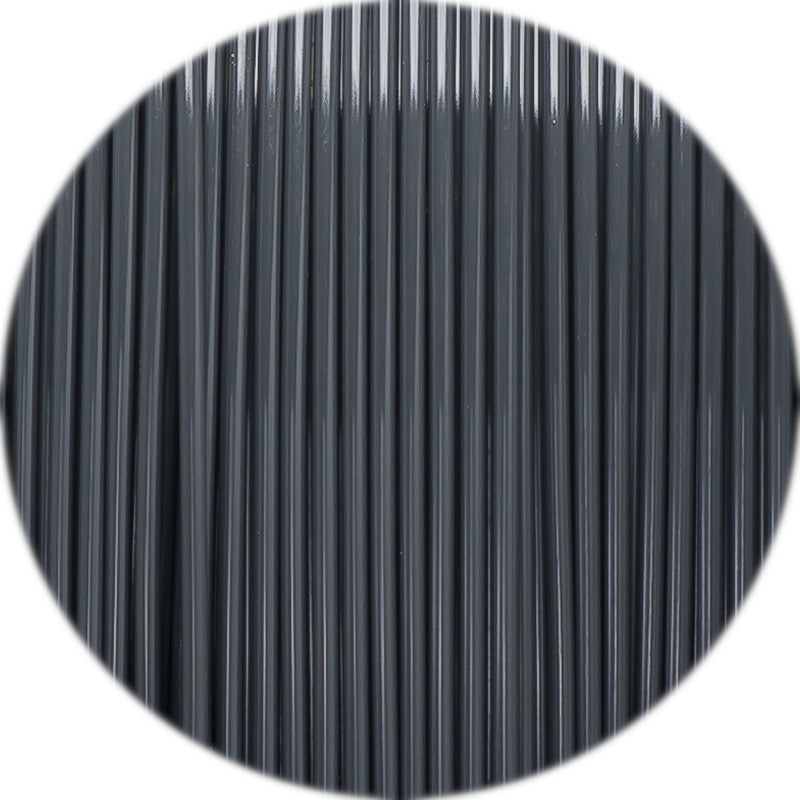

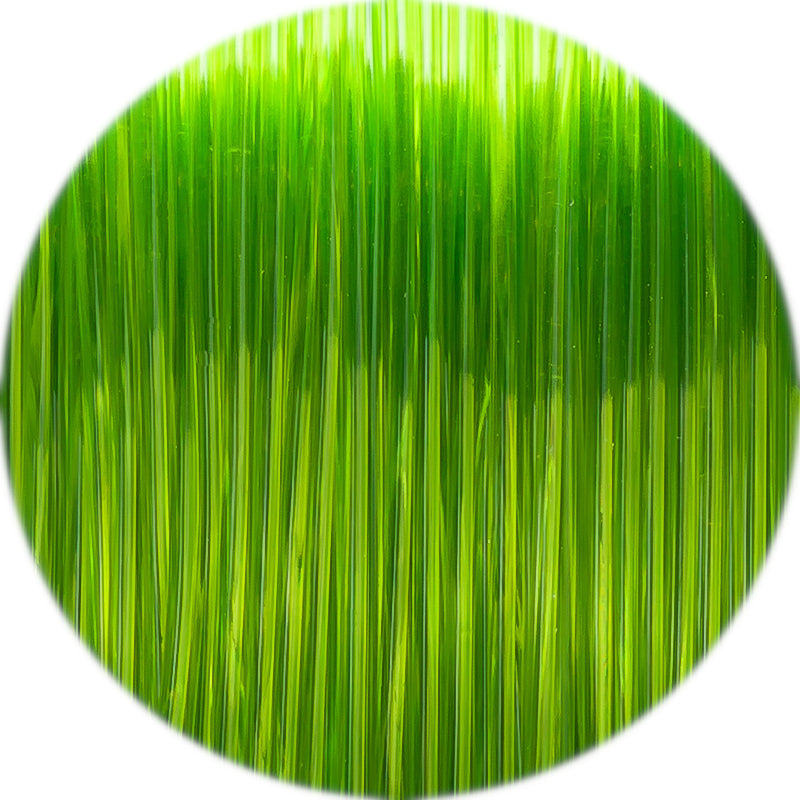

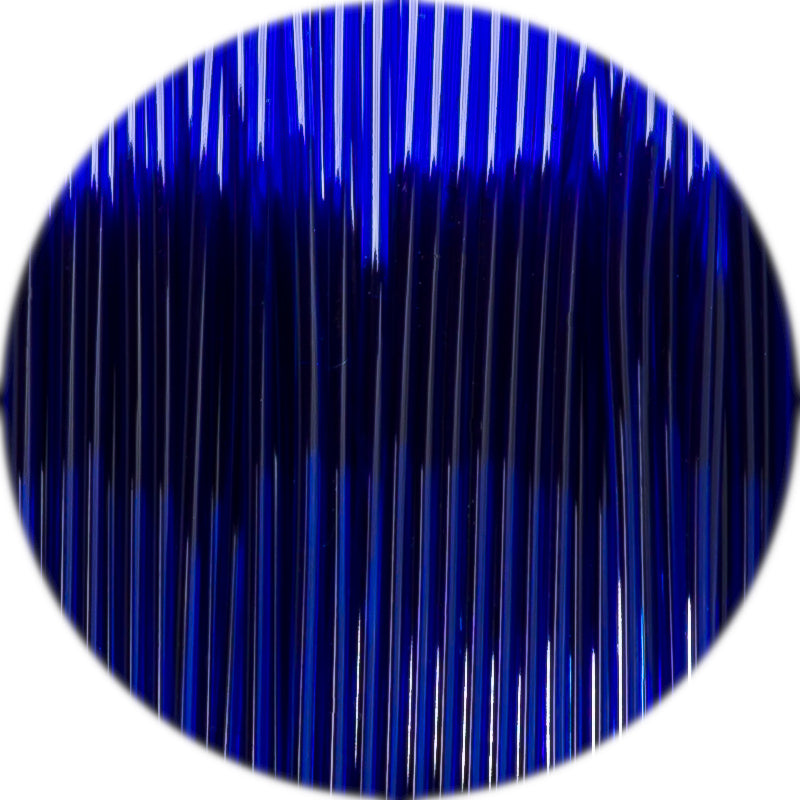

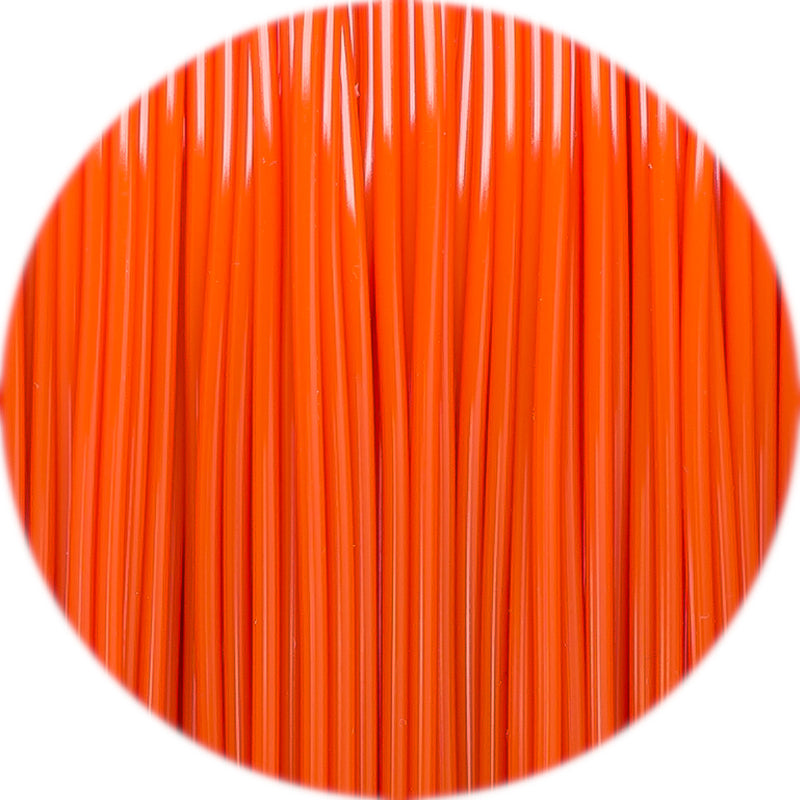

- High visual transparency makes it a great choice for decorative items where visual appeal and high durability are essential

- Easy to print with dimensional stability, and low shrinkage making this material great for beginners as well as more advanced professionals

- Suitable for contact with food* (Pure TR), and BPA free

Samples Collection:

You can also order an PCTG sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the exact right material for your project.

THE ALTERNATIVE TO PET-G

PCTG belongs to the same family of polyesters as the increasingly popular PET-G. Compared to its more popular counterpart, PCTG offers increased impact strength, temperature resistance and clarity, making it an excellent alternative to PET-G.

This filament does not require a heated chamber, which makes it ideal for use with home printers.

It ensures high dimensional stability, while low shrinkage prevents the model from cracking. This makes it an easy-to-print material, even for people without a lot of experience in 3D printing.

PCTG is characterized by a much higher impact strength compared to similar materials (e.g. PET-G). It achieves results in the region of 90 KJ/m2 (PET-G: 5-8 KJ/m2) in the Izod test (notched sample). PCTG also withstands higher temperatures (up to 76°C).

Fiberlogy PCTG is recyclable and approved for contact with food *.

This material is also BPA free.

-

Looking for more info? This material appears in this article The Strongest 3D Filaments: Everything to get you started.

"Special" Color Descriptions:

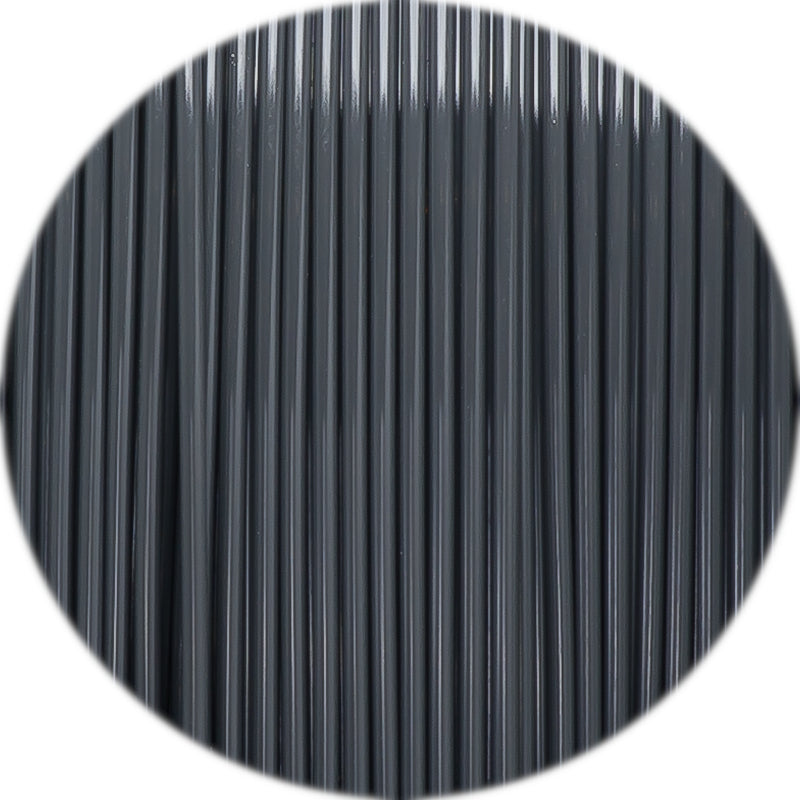

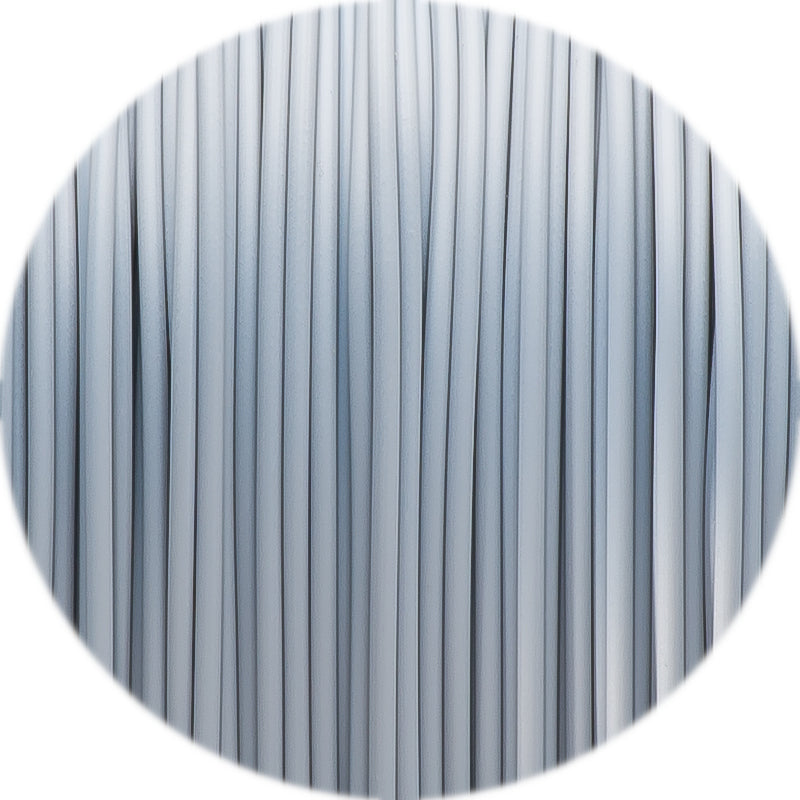

- Vertigo - Dark Gray base material, with a generous amount of small, silver flecks

- Onyx - Deep Black base material, with a generous amount of small, silver flecks

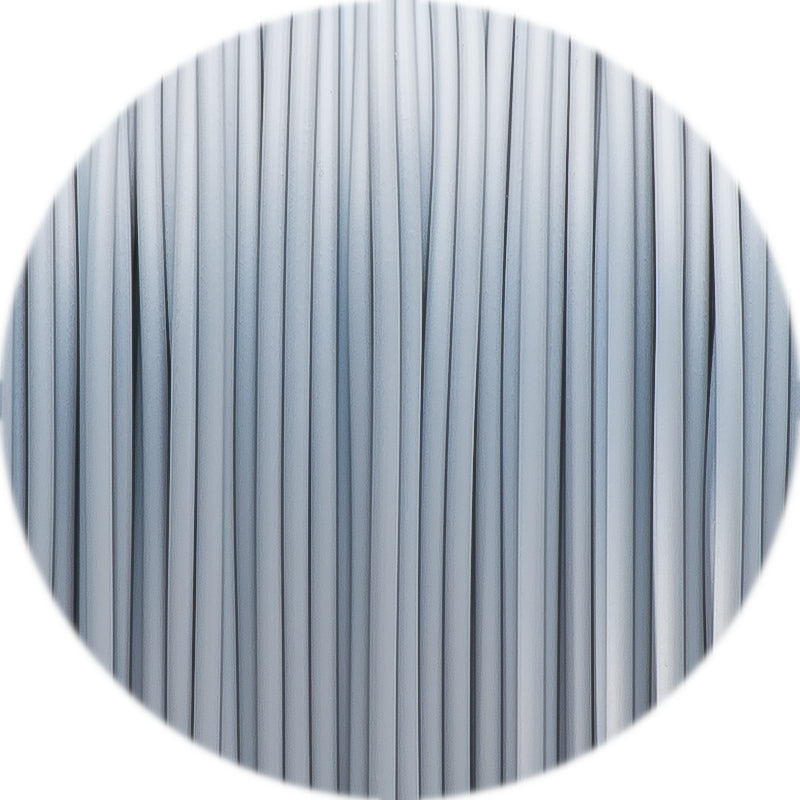

- INOX - Light Silver base material, with a light amount of small, silver flecks

* applies to the Pure TR version

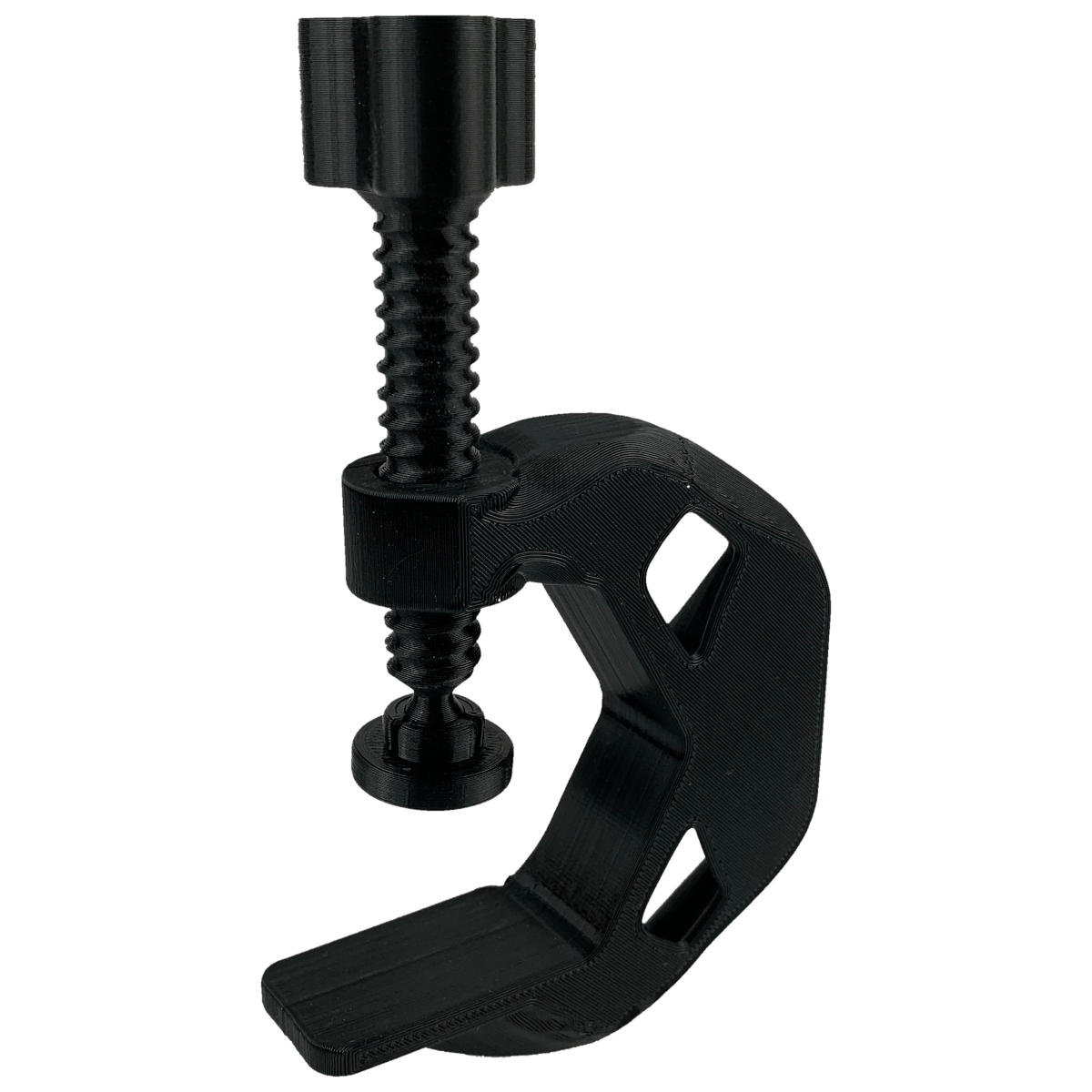

Printing Ideas and Applications:

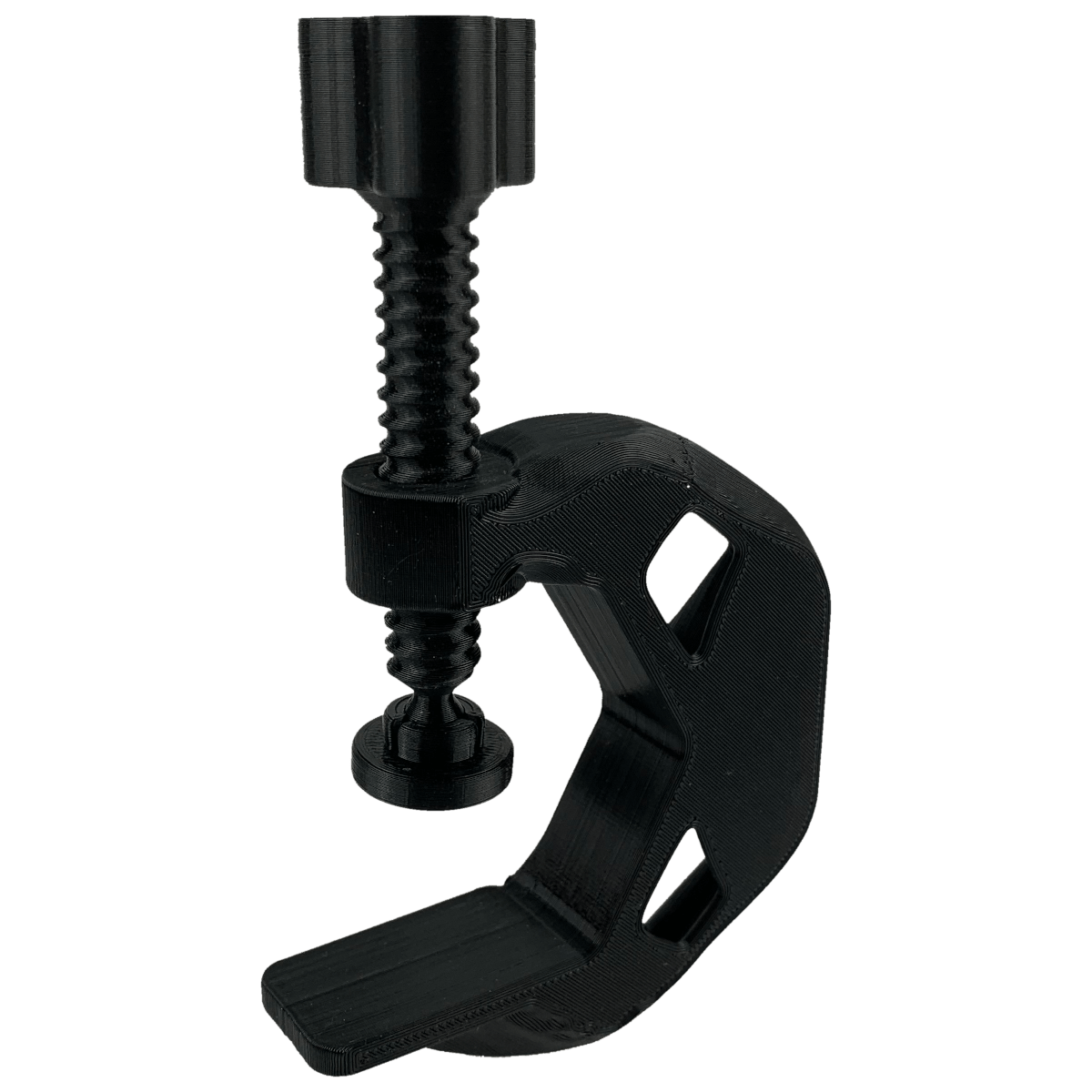

- INDUSTRY: spare parts, short series, utility models

- AUTOMOTIVE: elements in the engine compartment, housing of vehicle components, air intakes, fluid funnels

- SPORT: accessories, pads, airsoft elements

How to Print:

| Nozzle Temperature | 250-270°C |

| Bed Temperature | 90-110°C |

| Closed chamber | not required |

| Fan | 25-50% |

| Flowrate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | masking tape, PVA glue, hairspray |

| Retraction (direct) | 1-2 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Notes | Due to the strong adhesion to the bed, it is not recommended to print directly on its surface or on glass. This can lead to damage. We recommend using a masking tape. |

TDS and MSDS:

Net Weight: 0.75kg

FIBERLOGY 3D Printing filament comes wound on a premium white spool in vacuum sealed bag with a desiccate packet to maintain peak conditions.

Share

I am developing novel medical devices for use both within the clinic and outside. PCTG produces components that are very close to CAD drawing specs, with almost no shrinkage or warping. Also, PCTG components are robust to real-world abuse. Finally, since much of the work is trial and error, I often find the need to make minor changes, such as drilling an additional hole or filing and sanding to remove small amounts of material. PCTG is easy to file, sand, and drill, and allows me to obtain better fit, without the need to always re-design and re-print a component. My go-to materials are Onyx&White PCTG!

I am developing novel medical devices for use both within the clinic and outside. PCTG produces components that are very close to CAD drawing specs, with almost no shrinkage or warping. Also, PCTG components are robust to real-world abuse. Finally, since much of the work is trial and error, I often find the need to make minor changes, such as drilling an additional hole or filing and sanding to remove small amounts of material. PCTG is easy to file, sand, and drill, and allows me to obtain better fit, without the need to always re-design and re-print a component. My go-to materials are Onyx&White PCTG!