How to Print Fiberlogy Filaments: Print Settings, Info, and Notes

Share

Read This First:

First, welcome to the Narrow Path Family- we think you'll like it here.

Before getting started printing here a few tips to keep your materials in peek condition so you can get the best printing results.

- Always protect your filament from UV rays (direct/indirect sunlight/strong bright lights)

- The ideal temperature for storage is 15-25C (60-75F)

- We recommend you keep your filaments in a sealed bag when not in use (extra points if you can throw in an extra silicate bag, or two )

- When finished printing and transferring to storage slide the loose end of filament into the side notch or double holes. This is to secure the filament to avoid entanglements that can cause print failures. This also makes reloading the filament easier, and keeps your spool looking spiffy.

- If you have human or animal children it is best to keep the filament out of their reach. They can't help themselves, and mishaps will occur.

Print Settings for Fiberlogy Filaments:

Here you'll find all of the suggested basic print settings for getting started with your Fiberlogy filament.

We highly recommend you do a few test prints with your new materials and adjust the settings to meet the needs of your exact printer and what you desire to print.

Doing so will ensure you get the best print quality.

If you have other questions and you couldn't find the answer listed here, please feel free to email us at narrowpath3d@gmail.com and we will be happy to answer your questions.

Happy printing,

- Miriam @ Narrow Path 3D LLC

How to Print Fiberlogy Filaments: Print Settings, Info, and Notes

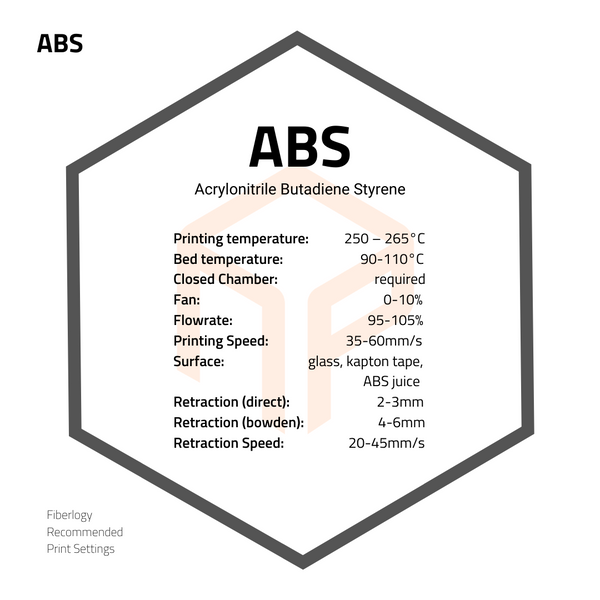

Recommended Settings: Fiberlogy ABS

Printing temperature: 250 – 265°C

Bed temperature: 90-110°C

Closed Chamber: required

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, kapton tape, ABS juice

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Recommended Settings: Fiberlogy ABS PLUS

Printing temperature: 250 – 265°C

Bed temperature: 90-110°C

Closed Chamber: recommended

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, kapton tape, ABS juice

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: For easiest removal from the bed it is highly recommended to not let the print cool on the build plate. When finished printing remove the print from the bed as soon as possible to avoid damage to the bed and best results.

Recommended Settings: Fiberlogy ESD ABS

Printing temperature: 250 – 265°C

Bed temperature: 90-110°C

Closed Chamber: recommended

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Recommended Settings: Fiberlogy ASA

Printing temperature: 255 – 275°C

Bed temperature: 90-110°C

Closed Chamber: not required

Fan: 0-25%

Flowrate: 90-100%

Printing Speed: < 100mm/s

Surface: glass, kapton tape, ABS juice

Retraction (direct): yes, 1-2mm

Retraction (bowden): yes, 4-6mm

Retraction Speed: 20-45mm/s

Notes: When printing without a heated chamber, it is recommended to avoid exposing the model to gusts of wind/drafts

Recommended Settings: Fiberlogy BVOH (water soluble support material)

Printing temperature: 190 – 220°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 75-100%

Flowrate: 95-105%

Printing Speed: < 35mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: Protect from moisture (Store filament in tightly sealed containers when not in use)

Recommended Settings: Fiberlogy CPE-HT

Printing temperature: 260 – 280°C

Bed temperature: 110-120°C

Closed Chamber: not required

Fan: 0-15%

Flowrate: 95-105%

Printing Speed: < 100mm/s

Surface: masking tape, PVA glue, hair spray

Retraction (direct): 1-2mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Drying Conditions: 60°C / 4h

Notes: Due to the strong adhesion to it, it is not recommended to print directly on the surface of the table or glass, as it may damage it. We recommend using masking tape, and to remove as soon as it is finished printing.

Recommended Settings: Fiberlogy Easy ABS

Printing temperature: 235-255°C

Bed temperature: 90-110°C

Closed Chamber: NOT required

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: < 100mm/s

Surface: glass, PVA glue, hairspray

Retraction (direct): 2-3mm

Retraction (bowden): 3-5mm

Retraction Speed: 20-45mm/s

Drying Conditions: 40°C / 4 hours

Notes: Easy ABS is compatible with HIPS when used as a support material

Recommended Settings: Fiberlogy EASY PET-G

Printing temperature: 230 – 250°C

Bed temperature: 75-85°C

Closed Chamber: not required

Fan: 0-25%

Flowrate: 95-105%

Printing Speed: < 100mm/s

Surface: masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-5mm

Retraction Speed: 20-45mm/s

Notes: Due to the strong adhesion to it, it is not recommended to print directly on the surface of the table or glass, as it may damage it. We recommend using masking tape.

Recommended Settings: Fiberlogy PET-G

Printing temperature: 230 – 250°C

Bed temperature: 90°C

Closed Chamber: not required

Fan: 0-25%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-5mm

Retraction Speed: 20-45mm/s

Notes: Due to the strong adhesion to it, it is not recommended to print directly on the surface of the table or glass, as it may damage it. We recommend using masking tape.

Recommended Settings: Fiberlogy PCTG

Printing temperature: 250 – 270°C

Bed temperature: 90-110°C

Closed Chamber: not required

Fan: 25-50%

Flowrate: 90-100%

Printing Speed: < 100mm/s

Surface: masking tape, PVA glue, hair spray

Retraction (direct): 1-2mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Drying Conditions: 60°C / 4h

Notes: Due to the strong adhesion to it, it is not recommended to print directly on the surface of the table or glass, as it may damage it. We recommend using masking tape.

Recommended Settings: Fiberlogy EASY PLA

Printing temperature: 200 – 230°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 75-100%

Flowrate: 90-100%

Printing Speed: < 100mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: Easy PLA Aurora – recommended minimum 0,5 mm nozzle. Easy PLA White – due to the dye, the suggested minimum printing temperature is 230°C.

Recommended Settings: Fiberlogy HD PLA

Printing temperature: 200 – 230°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 75-100%

Flowrate: 90-100%

Printing Speed: < 100mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: HD PLA White – due to the dye, the suggested minimum printing temperature is 230°C

Recommended Settings: Fiberlogy IMPACT PLA

Printing temperature: 230 – 245°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 75-100%

Flowrate: 90-100%

Printing Speed: < 100mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: IMPACT PLA White – due to the dye, the suggested minimum printing temperature is 230°C

Recommended Settings: Fiberlogy PLA MINERAL

Printing temperature: 190 – 210°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 75-100%

Flowrate: 90-100%

Printing Speed: < 35-60mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

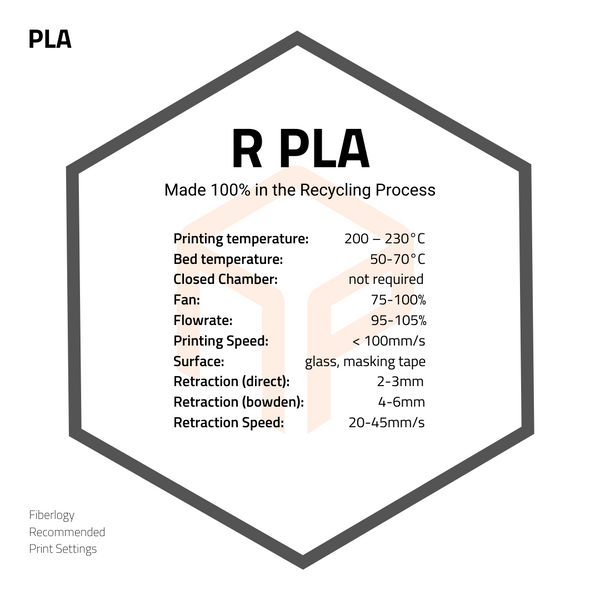

Recommended Settings: Fiberlogy R PLA

Printing temperature: 210 – 230°C

Bed temperature: 950-70°C

Closed Chamber: not required

Fan: 75-100%

Flowrate: 95-105%

Printing Speed: < 100mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Recommended Settings: Fiberlogy FIBERFLEX 30D

Printing temperature: 200 – 220°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 50-75%

Flowrate: 95-110%

Printing Speed: > 35mm/s

Surface: glass, masking tape

Retraction (direct): 1-2mm

Retraction Speed: 10-30mm/s

Notes: For more in-depth tips, tricks and troubleshooting flexible filaments check out this page.

Recommended Settings: Fiberlogy FIBERFLEX 40D

Printing temperature: 200 – 220°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 50-75%

Flowrate: 105-110%

Printing Speed: < 45mm/s

Surface: glass, masking tape

Retraction (direct): 1-2mm

Retraction Speed: 10-30mm/s

Notes: To remove the print easier, it is recommended to heat the bed to 110°C

Notes: For more in-depth tips, tricks and troubleshooting flexible filaments check out this page.

Recommended Settings: Fiberlogy MattFlex 40D

Printing temperature: 210 – 230°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 50-75%

Flowrate: 105-110%

Printing Speed: < 60mm/s

Surface: glass, masking tape

Retraction (direct): 1-2mm

Retraction Speed: 10-30mm/s

Notes: To remove the print easier, it is recommended to heat the bed to 110°C

Notes: For more in-depth tips, tricks and troubleshooting flexible filaments check out this page.

Recommended Settings: Fiberlogy FIBERSILK

Printing temperature: 210 – 230°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 75-100%

Flowrate: 90-100%

Printing Speed: 35-60mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: There is a visible swelling of the material as it extrudes from the nozzle while loading the filament or printing with it. This is a completely natural effect that results from the surface tension of the polymers making up the filament.

Recommended Settings: Fiberlogy FIBERWOOD

Printing temperature: 190 – 210°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 75-100%

Flowrate: 90-100%

Printing Speed: 35-60mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: To avoid a situation where the nozzle gets clogged with wood particles, we recommend cleaning the extruder after each FiberWood print by using any type of PLA filament.

Recommended minimum 0,5 mm nozzle

Recommended Settings: Fiberlogy HIPS

Printing temperature: 230 – 245°C

Bed temperature: 80-100°C

Closed Chamber: recommended

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Recommended Settings: Fiberlogy NYLON PA12

Printing temperature: 255 – 270°C

Bed temperature: 90-110°C

Closed Chamber: required

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, PVA glue, hairspray

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Recommended Settings: Fiberlogy NYLON PA12+CF15

Printing temperature: 255 – 270°C

Bed temperature: 90-110°C

Closed Chamber: not required

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: The material has highly abrasive properties. We recommend the use of hardened steel or ruby nozzles.

Recommended Settings: Fiberlogy NYLON PA12+CF5

Printing temperature: 255 – 270°C

Bed temperature: 90-110°C

Closed Chamber: required

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: The material has highly abrasive properties. We recommend the use of hardened steel or ruby nozzles.

Recommended Settings: Fiberlogy NYLON PA12+GF15

Printing temperature: 255 – 270°C

Bed temperature: 90-110°C

Closed Chamber: required (in most cases)

Fan: 0-25%

Flowrate: 90-100%

Printing Speed: 35-60mm/s

Surface: PEI, glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: The material has highly abrasive properties. We recommend the use of hardened steel or ruby nozzles. We also recommend you wear gloves (to avoid the possibility of micro damages on the skin from the glass particles). Use a dust mask and protective glasses when processing.

Recommended Settings: Fiberlogy PP (polypropylene)

Printing temperature: 220 – 250°C (we recommend starting at the higher end at 250C)

Bed temperature: 70-80°C

Closed Chamber: not required

Fan: 0-50% (we recommend 0% fan to start)

Flowrate: 100-105%

Printing Speed: < 45mm/s

Surface: packing tape, Vision Minor, Magigoo for Polypropylene

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s