Narrow Path 3D

FIBERLOGY ABS+GF - lightweight and durable glass fiber 3D printing filament , 1.75mm, 0.75kg

FIBERLOGY ABS+GF - lightweight and durable glass fiber 3D printing filament , 1.75mm, 0.75kg

Couldn't load pickup availability

Key Features at a glance:

- Fiberlogy ABS+GF - Versatile and strong with excellent mechanical properties

- Ideal for the production of products operating in a wide temperature range

- High adhesion minimizes the risk of cracking and peeling off prints

- ABS+GF filament is an excellent choice for many applications, especially where mechanical strength, exceptional stiffness and tensile strength with dimensional stability are required.

Properties:

- high stiffness and tensile strength

- lightweight

- lower shrinkage and better dimensional stability than standard ABS

- impact and wear resistance

- easy to print

- matte finish that hides layer lines

Samples Collection:

You can also order an ABS+GF sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the exact right material for your project.

ABS reinforced with Fiberglass - Lightweight & Durable

ABS+GF is a 3D printing filament that combines the versatility of ABS with the strength of fiberglass reinforcement.

The resulting prints are rigid yet lightweight, while being resistant to deformation and elevated temperatures. This makes it an excellent choice for projects demanding high mechanical properties and wear resistance while maintaining low weight, even under demanding operating conditions.

The ABS+GF filament has been specially modified to improve impact resistance, maintaining high durability against shocks.

Compared to standard ABS filament, the glass fiber-enhanced material exhibits better bed adhesion, improved layer bonding and reduced shrinkage, increasing dimensional accuracy.

It also provides weight and cost reduction compared to other composite materials. These properties make Fiberlogy ABS+GF the ideal choice for manufacturing drone components and lightweight structures where the combination of strength and minimal weight is essential.

Printing Ideas and Applications:

- INDUSTRY: drone components, clamps, protective covers, parts subject to mechanical stress;

- AUTOMOTIVE: reinforced car accessories, interior components, brackets,

- TOOLS: functional workshop equipment, vices, mounting fixtures;

- PROTOTYPING: models requiring stiffness and durability.

How to Print:

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 270-280°C |

| Bed Temperature | 90°C |

| Closed chamber | recommended |

| Fan | 10-30% |

| Printing Speed | <150 mm/s |

| Surface |

Smooth PEI + adhesive Textured PEI Glass + adhesive |

| Drying conditions | 80°C / 4h |

| Notes |

The material has highly abrasive properties. We recommend the use of hardened steel or ruby nozzles. Wear gloves (the possibility of micro damages on the skin). Use a dust mask and protective glasses when processing. For best printing results, we recommend enabling part cooling fan for overhangs (fan speed for overhangs): 70-80%. |

TDS:

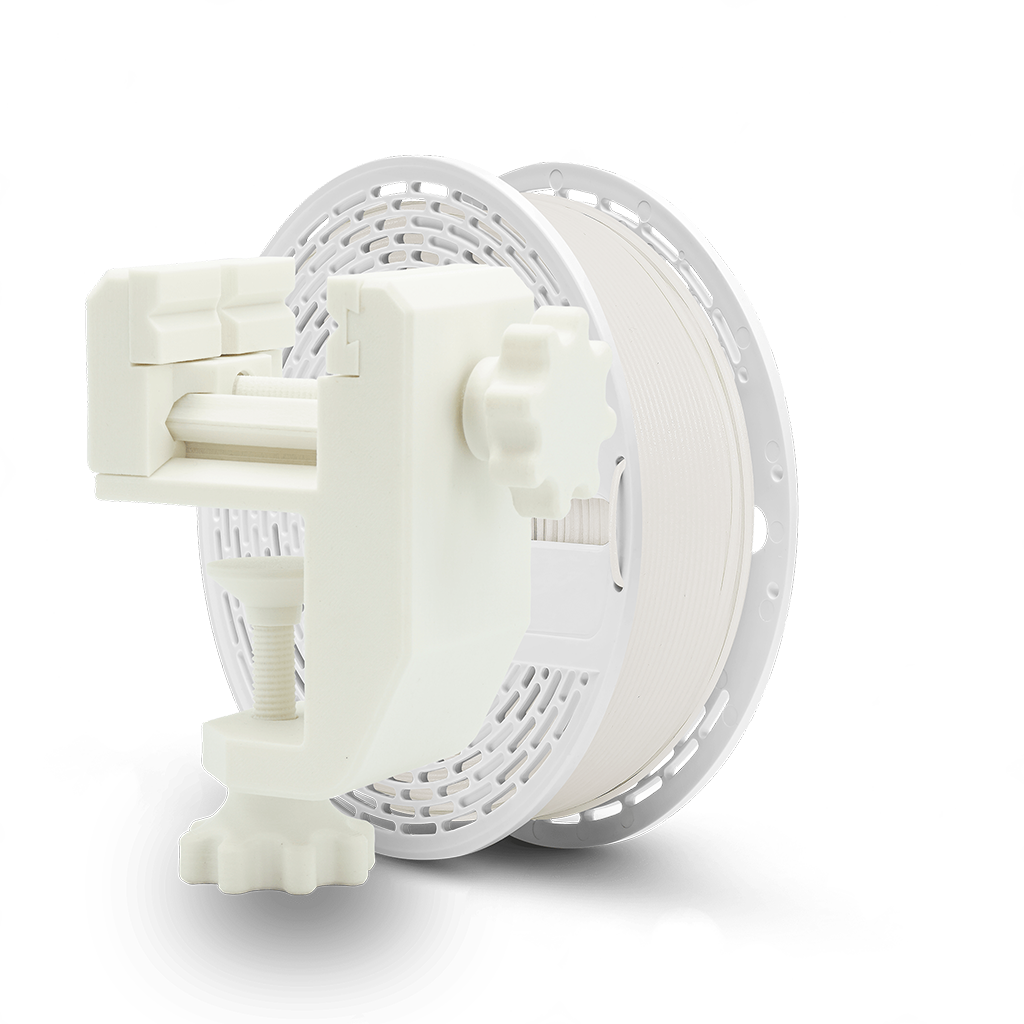

Net Weight: 0.75kg

FIBERLOGY 3D Printing filament comes wound on a premium white spool in vacuum sealed bag with a desiccate packet to maintain peak conditions.

Share