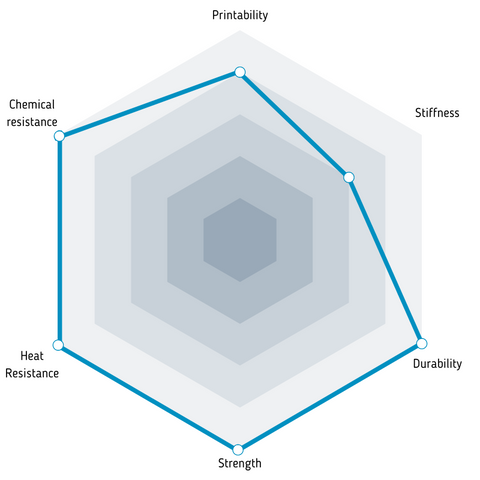

PA12 + GF15 is another material offered by Fiberlogy, which is a derivative of Nylon PA12. It was created by reinforcing it with glass fiber (GF), which constitutes 15% of the product. This made it possible to significantly increase the durability, stiffness, and thermal and chemical resistance compared to pure Nylon. PA12 + GF15 has a stiffness of 3.6 GPa and a temperature resistance of up to 170°C.

This filament offers greater flexibility, making it ideal for applications operating under variable loads and exposed to impacts, unlike Nylon with an addition of glass fiber, available as Fiberlogy PA12 + CF5 and PA12 + CF15, .

The very low shrinkage ensures high dimensional stability. This combined with high durability makes engineering excellence achievable at home. This filament does not require a heated chamber. However, due to the high abrasiveness, steel or ruby nozzles should be used for printing in order to prevent excessive wear.

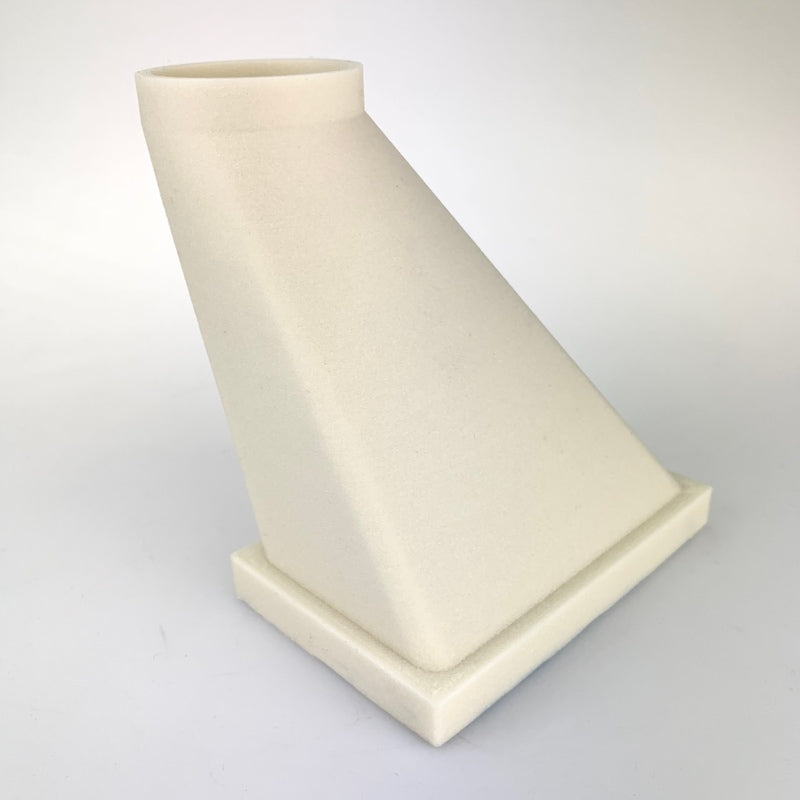

Applications in 3D Printing:

- AUTOMOTIVE: elements in the engine compartment, housing of vehicle components, air intakes, fluid fillers

- INDUSTRY: spare parts, short series, utility models

- MEDICINE: prostheses, medical equipment

- SPORT: accessories, pads, airsoft elements

How to Print:

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

Printing temperature: 255 – 270°C

Bed temperature: 90-110°C

Closed Chamber: required

Fan: 0-25%

Flowrate: 90-100%

Printing Speed: 35-60mm/s

Surface: PEI, glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Important Notes: The material is highly abrasive. We recommend the use of hardened steel or ruby nozzles. Wear gloves (the possibility of micro damages on the skin). Use a dust mask and protective glasses when processing.