Fiberlogy is created by enthusiasts with many years of experience in the 3D printing realm. We are constantly looking for inspiration to create new materials. We create possibilities in the 3D printing world every year with new products.

This is a list of some of the strongest filaments currently available from Fiberlogy @ Narrow Path 3D.

IMPACT PLA - RESISTANCE and PRECISION

Key Features:

- Fiberlogy IMPACT PLA: Increased impact strength compared with PLA (up to 800%) and ABS (up to 50%)

- Excellent for highly detailed prints

- Above average bed adhesion

- This material is very easy to use; expect similar outcomes that you would have with Fiberlogy EASY PLA settings

- Engineered and created in Poland using highly specialized machinery and carefully selected raw materials

Samples Collection:

You can also order an IMPACT PLA Sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the exact right material for your project.

More Info:

IMPACT PLA offers properties that are similar or better than those of ABS filaments while keeping the ease and security of the printing process typical with traditional PLA.

This technical filament ensures increased resistance to cracking and breaking due to its high impact strength and a higher resistance to high temperatures.

With these properties, IMPACT PLA is ideal for creating demanding prints working in extreme conditions while maintaining the highest level of attention to detail.

Fiberlogy IMPACT PLA is a tried and tested filament for printing functional prototypes and large heavy-duty tools.

"Special" Color Descriptions:

- Vertigo - Dark Gray base material, with a generous amount of small, silver flecks

- Onyx - Deep Black base material, with a generous amount of small, silver flecks

Find it here: Fiberlogy IMPACT PLA Filament - Best PLA up to 800% Impact Strength

Printing Ideas and Applications:

- End-Use Products/Parts: containers, handles

- Prototypes: tools, conceptual models, switching parts, mechanical parts, elements requiring resistance to higher temperatures

- Spare Parts: elements of machines, devices, vehicles, electronic equipment

- Tools and Tool Elements: gears, racks, elements requiring high strength

- Toys: blocks, robots or their parts, car parts

How to Print:

Printing temperature: 230 – 245°C

Bed temperature: 50-70°C

Closed Chamber: not required

Fan: 75-100%

Flowrate: 90-100%

Printing Speed: < 100mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: IMPACT PLA White – due to the dye, the suggested minimum printing temperature is 230°C

Important Note: This material is very easy to use; expect similar outcomes that you would have with Fiberlogy EASY PLA settings

TDS and MSDS:

Find it here: Fiberlogy IMPACT PLA Filament - Best PLA up to 800% Impact Strength

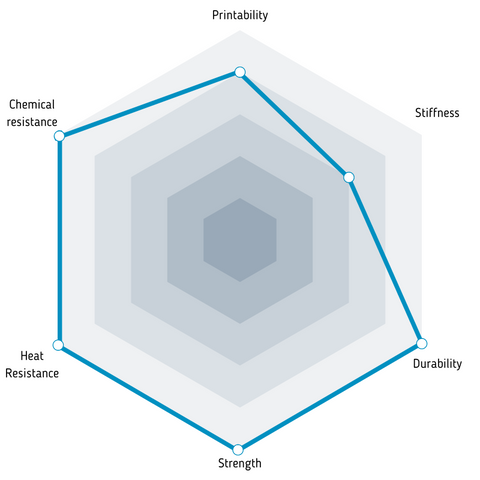

FIBERLOGY PCTG - THE ALTERNATIVE TO PET-G

Key Features at a glance:

- Fiberlogy PCTG offers excellent impact strength (up to 20X times greater than standard PET-G)

- Excellent chemical resistance (see TDS below for detailed resistances)

- High visual transparency makes it a great choice for decorative items where visual appeal and high durability are essential

- Easy to print with dimensional stability, and low shrinkage making this material great for beginners as well as more advanced professionals

- Suitable for contact with food* (Pure TR), and BPA free

Samples Collection:

You can also order an PCTG sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the exact right material for your project.

More info:

PCTG belongs to the same family of polyesters as the increasingly popular PET-G. Compared to its more popular counterpart, PCTG offers increased impact strength, temperature resistance and clarity, making it an excellent alternative to PET-G.

This filament does not require a heated chamber, which makes it ideal for use with home printers.

It ensures high dimensional stability, while low shrinkage prevents the model from cracking. This makes it an easy-to-print material, even for people without a lot of experience in 3D printing.

PCTG is characterized by a much higher impact strength compared to similar materials (e.g. PET-G). It achieves results in the region of 90 KJ/m2 (PET-G: 5-8 KJ/m2) in the Izod test (notched sample). PCTG also withstands higher temperatures (up to 76°C).

Fiberlogy PCTG is recyclable and approved for contact with food *.

This material is also BPA free.

* applies to the Pure TR version

Find it Here: FIBERLOGY PCTG - Professional Alternative to PET-G

Printing Ideas and Applications:

- INDUSTRY: spare parts, short series, utility models

- AUTOMOTIVE: elements in the engine compartment, housing of vehicle components, air intakes, fluid funnels

- SPORT: accessories, pads, airsoft elements

How to Print:

| Nozzle Temperature | 250-270°C |

| Bed Temperature | 90-110°C |

| Closed chamber | not required |

| Fan | 25-50% |

| Flowrate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | masking tape, PVA glue, hairspray |

| Retraction (direct) | 1-2 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Notes | Due to the strong adhesion to the bed, it is not recommended to print directly on its surface or on glass. This can lead to damage. We recommend using a masking tape. |

TDS and MSDS:

Find it Here: FIBERLOGY PCTG - Professional Alternative to PET-G

NYLON PA12 - EVOLUTION OF DURABILITY

Key Features:

- Unbreakable- extreme toughness and durability makes Fiberlogy NYLON PA12 best suited for prints requiring strength and durability that hold up over time/continual use, while offering flexibility (Example: gears, rollers, skate board wheels, and more)

- The high flexibility of Nylon PA12 makes it a great option for prints with thin walls where strength and flexibility are both required

- Nylon PA12 is best defined by its ability to withstand wear and tear (ABS is better known for its strength)

- Engineered and created in Poland using highly specialized machinery and carefully selected raw materials

More info:

Thanks to its resistance to high temperatures, alcohol and chemicals, Nylon is particularly useful for mechanical and technical applications.

It is extremely durable, strong and unbreakable.

It is easily machined with tools designed for metal processing and it is also easily painted, which makes it even more versatile and functional.

It is incredibly flexible – it expands by 50% before it breaks. Keep in mind it is not resistant to concentrated alkalis and acids.

Find it here: Fiberlogy NYLON PA12 - Extremely Durable

Printing Ideas and Applications:

- TOYS OR TOY PARTS: characters, animals, constructions, houses, vehicles, dice

- GADGETS OR PARTS: key rings, stands, phone cases

- PROTOTYPES: new products, conceptual models

- JEWELRY PARTS: earrings, bracelets, beads, necklaces

- DECORATIONS: Christmas tree decorations, pendants

How to Print:

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

Nozzle Temp: 255-270 C

Bed Temp: 90-110 C

Closed Chamber: Required

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, PVA glue, hairspray, magigoo

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

TDS and MSDS:

Fiberlogy NYLON PA12 - Extremely Durable Filament 3D

NYLON PA12+CF15 - CARBON EXCELLENCE

Features:

- Nylon PA12+CF15 is characterized by an impressive matte finish- prints created with Nylon PA12+CF are hard to distinguish from non printed parts thanks to the matte texture of the filament that helps mask layer lines

- The specialized carbon fiber in the filament makes prints lighter while still maintaining the impressive structural integrity of the printed piece

- PA12+CF has 2x the tensile strength and more than 2x the stiffness of Nylon PA12

- Engineered and created in Poland using highly specialized machinery and carefully selected raw materials

Samples Collection:

You can also order a NYLON PA12+CF15 / CF5 Sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the right material for your project.

More Info:

PA12+CF is yet another manifestation of the technical capabilities of filament PA12 which has been reinforced with 5% and 15% addition of carbon fibers.

It is characterized by high thermal resistance and less shrinkage compared to the unmodified Nylon PA12.

The application of carbon fiber allows for a reduction of weight of the component while maintaining its high structural stiffness.

PA12+CF has a range of applications across the industry, including the automotive and the engineering sectors, lending itself to the creation of advanced prototypes, drones and final products which require increased durability while reducing their weight.

* provided that appropriate print parameters are selected and a correct print structure is maintained.

Find it Here: Fiberlogy NYLON PA12+CF15 - Professional Carbon Fiber Filament

Printing Ideas and Applications:

- Prototypes: car parts, drones, high durability mechanical components

- Substitutes for Metal Elements

- End-use products

- Part Engineering

- Tools and Their Elements

How to Print:

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for your specific printer and printing conditions.

Printing temperature: 255 – 270°C

Bed temperature: 90-110°C

Closed Chamber: not required

Fan: 0-10%

Flowrate: 95-105%

Printing Speed: 35-60mm/s

Surface: glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Important Note: The material is highly abrasive. We recommend the use of hardened steel or ruby nozzles.

Sizes Available : 0.5 kg and 2.5kg spool sizes available

TDS and MSDS:

Fiberlogy NYLON PA12+CF15 - Professional Carbon Fiber Filament

NYLON PA12+GF15 - DURABILITY AND RESISTANCE

Key Features:

- Prints created with Nylon PA12+GF15 can highlight the perfect combination of high durability, impact resistance, dimensional stability and resistance to high temperatures (up to 170°C) and chemicals

- Engineering excellence achievable from home printers

- Nylon PA12+GF15 is resistant to material fatigue; when printed parts bare weight on/off repeatedly the print continues to hold its shape over time.

- Possible to print on an open printer

- Available in Natural and Black

- Engineered and created in Poland using highly specialized machinery and carefully selected raw materials

Samples Collection:

You can also order a NYLON PA12+GF15 Sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the exact right material for your project.

DURABILITY AND RESISTANCE

PA12 + GF15 is a new material option of Nylon PA12.

It was created by reinforcing it with glass fiber (GF), which constitutes 15% of the product. This made it possible to significantly increase:

- Overall Durability

- Stiffness

- Thermal and chemical resistance compared to pure Nylon PA12

GF15 has a stiffness of 3.6 GPa and a temperature resistance of up to 170°C.

This filament offers greater flexibility, making it ideal for applications operating under variable loads and exposed to impacts, unlike Nylon with an addition of glass fiber, available as Fiberlogy PA12 + CF5 and PA12 + CF15, .

The very low shrinkage ensures high dimensional stability. This combined with high durability makes engineering excellence achievable at home. This filament does not require a heated chamber. However, due to the high abrasiveness, steel or ruby nozzles should be used for printing in order to prevent excessive wear.

Find it here: Fiberlogy NYLON PA12+GF15 - DURABILITY AND RESISTANCE

Applications in 3D Printing:

- AUTOMOTIVE: elements in the engine compartment, housing of vehicle components, air intakes, fluid fillers

- INDUSTRY: spare parts, short series, utility models

- MEDICINE: prostheses, medical equipment

- SPORT: accessories, pads, airsoft elements

How to Print:

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

Printing temperature: 255 – 270°C

Bed temperature: 90-110°C

Closed Chamber: required

Fan: 0-25%

Flowrate: 90-100%

Printing Speed: 35-60mm/s

Surface: PEI, glass, masking tape

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Important Notes: The material is highly abrasive. We recommend the use of hardened steel or ruby nozzles. Wear gloves (the possibility of micro damages on the skin). Use a dust mask and protective glasses when processing.

TDS and MSDS:

Net Weight : 0.5 kg

Fiberlogy NYLON PA12+GF15 - DURABILITY AND RESISTANCE

CPE HT - THE LATEST GENERATION OF CO-POLYESTERS

Key Features at a glance:

- FIBERLOGY CPE HT features one of the highest temperature resistances of materials able to be printed on the standard home use FDM 3D printer - Prints made with CPE HT can withstand temperatures up to 110°C -

- No closed heated chamber required

- No odor

- BPA, BPS and styrenes-free

- Excellent mechanical strength comparable to the PC line

- Pure Translucent color

Samples Collection:

You can also order a CPE HT sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the exact right material for your project.

THE NEXT GENERATION OF CO-POLYESTERS

Fiberlogy CPE HT is a modern co-polyester that stands out for its high mechanical and temperature resistance. As a member of the polymers family, which includes PET-G and PCTG, it surpasses them in terms of resistance to high temperatures, even up to 110°C. Like other related materials, this filament has a high resistance to chemicals and lipids.

It is odorless and BPA, BPS and styrene free and can be used to create food contact parts *. CPE HT will find numerous applications that require resistance to degrading conditions, such as in a dishwasher or in the process of chemical sterilization or UV radiation.

Fiberlogy CPE HT is an attractive alternative to polycarbonate filaments. Having similar strength parameters as PC, it does not share with it the characteristics that make it difficult to work with and use.

* applies to the filament in the Pure TR version

Find it here: FIBERLOGY CPE HT - Easy and Durable Food Safe 3D Filament for Makers

Printing Ideas and Applications:

- HOME USE: food storage containers, reusable dishes

- CHILDREN’S ARTICLES: toys and spare parts, accessories for babies

- HOUSEHOLD APPLIANCES: appliance housings, spare parts, utility prototypes, water filters

How to print?

The following parameters are suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 260-280°C |

| Bed Temperature | 110-120°C |

| Closed chamber | not required |

| Fan | 0-15% |

| Flowrate | 95-105% |

| Printing Speed | < 100 mm/s |

| Surface | masking tape, PVA glue, hairspray |

| Retraction (direct) | 1-2 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Notes | Due to the strong adhesion to the bed, it is not recommended to print directly on its surface or on glass. This can lead to damage. We recommend using a masking tape, and to remove as soon as finished printing. |

TDS and MSDS:

Find it here: FIBERLOGY CPE HT - Easy and Durable Food Safe 3D Filament for Makers

-

FIBERLOGY PCTG+GF10 - MODERN COPOLYESTER WITH FIBERGLASS

Key Features at a glance:

- Fiberlogy PCTG+GF offers excellent impact strength (up to 20X times greater than standard PET-G)

- Excellent chemical resistance (see TDS below for detailed resistances)

- High visual transparency makes it a great choice for decorative items where visual appeal and high durability are essential

- Easy to print with dimensional stability, and low shrinkage making this material great for beginners as well as more advanced professionals

Samples Collection:

You can also order an PCTG+GF sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the exact right material for your project.

MODERN COPOLYESTER FOR ADVANCED PROJECTS

PCTG+GF filament is our latest product for 3D printing enthusiasts, combining the strength and versatility of modern copolyester with the unique properties of glass fiber. It is a technical filament with high impact strength, ideal for advanced projects where typical polymers are not enough.

Glass fiber adds unique capabilities to the filament, creating a product with higher strength and stiffness, while remaining resistant to external conditions and chemicals. The properties of the filament make it ideal for printing machine parts, tools or outdoor applications.

Fiberlogy PCTG+GF is a guarantee of trouble-free printing. Low shrinkage, excellent table adhesion and the ability to print in 3D printers not equipped with a closed chamber, make this filament can be used on any printer.

Its users will also appreciate the matte, rough finish, giving the models a perfect look.

Printing Ideas and Applications:

- PROTOTYPING: functional prototypes, specialized tools, low-volume production

- AUTOMOTIVE: elements of covers, connectors, housings of electronic components

- ELECTRONICS: enclosures with increased resistance to impacts, chemicals and temperatures

How to Print:

| Nozzle Temperature | 250-270°C |

| Bed Temperature | 90-110°C |

| Closed chamber | not required |

| Fan | 0-25% |

| Flowrate | 90-100% |

| Printing Speed | 30-60 mm/s |

| Surface | masking tape, PVA glue, hairspray |

| Retraction (direct) | 1-2 mm |

| Retraction (bowden) | 3-5 mm |

| Retraction Speed | 20-45 mm/s |

| Drying conditions | 60°C / 4h |

| Notes | Due to the strong adhesion to the bed, it is not recommended to print directly on its surface or on glass. This can lead to damage. We recommend using a masking tape. |

-

What are you most interested in trying first?

Samples of the materials are a great way to get started and compare different parameters and features of each unique filament.

View all Fiberlogy Filament Samples and Sample Packs: Fiberlogy Samples Collection

-

Continue reading through our detailed reviews of Fiberlogy 3D materials to find the right material for your project.

If you're looking for food grade 3D filaments check out this post: Food Safe 3D printing materials from Fiberlogy

Looking for Flexibles? Print Flexible 3D Filaments Easy with "Fiberlogy"

If you're new to 3D printing and wanting the easiest materials to print: The Easiest Fiberlogy 3D Filaments to Use and How to Print Them